Portfolio

OUR WORK

A SHOWCASE OF OUR WORK

All

Website Design

Logo Design

Design Work

All

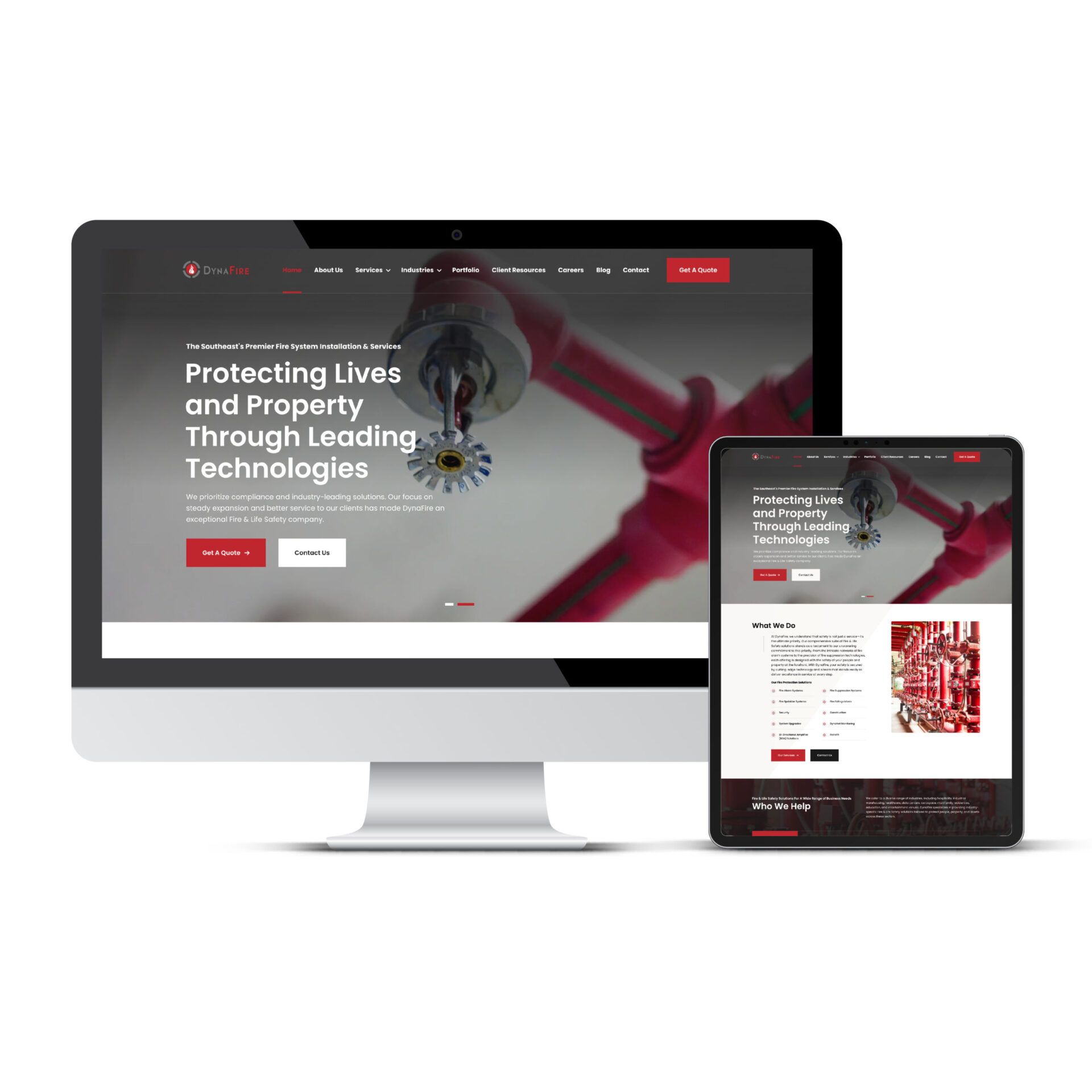

DynaFire

Office Assets, LLC

Website Design Services Portfolio MockUp for Office Assets, LLC

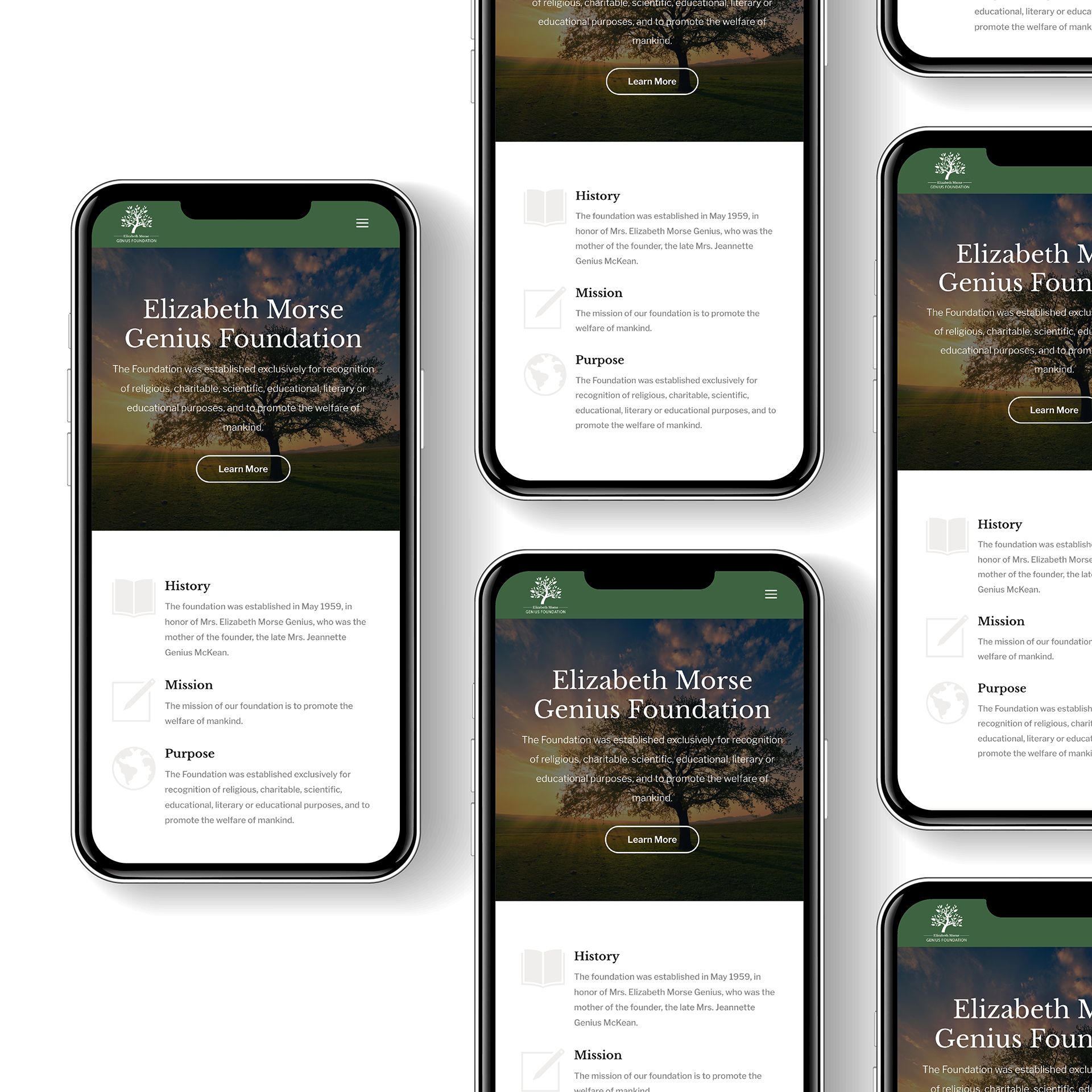

Elizabeth Morse Genius Foundation

Creative Environmental Solutions

Website Design Services Portfolio MockUp for Creative Environmental Solutions

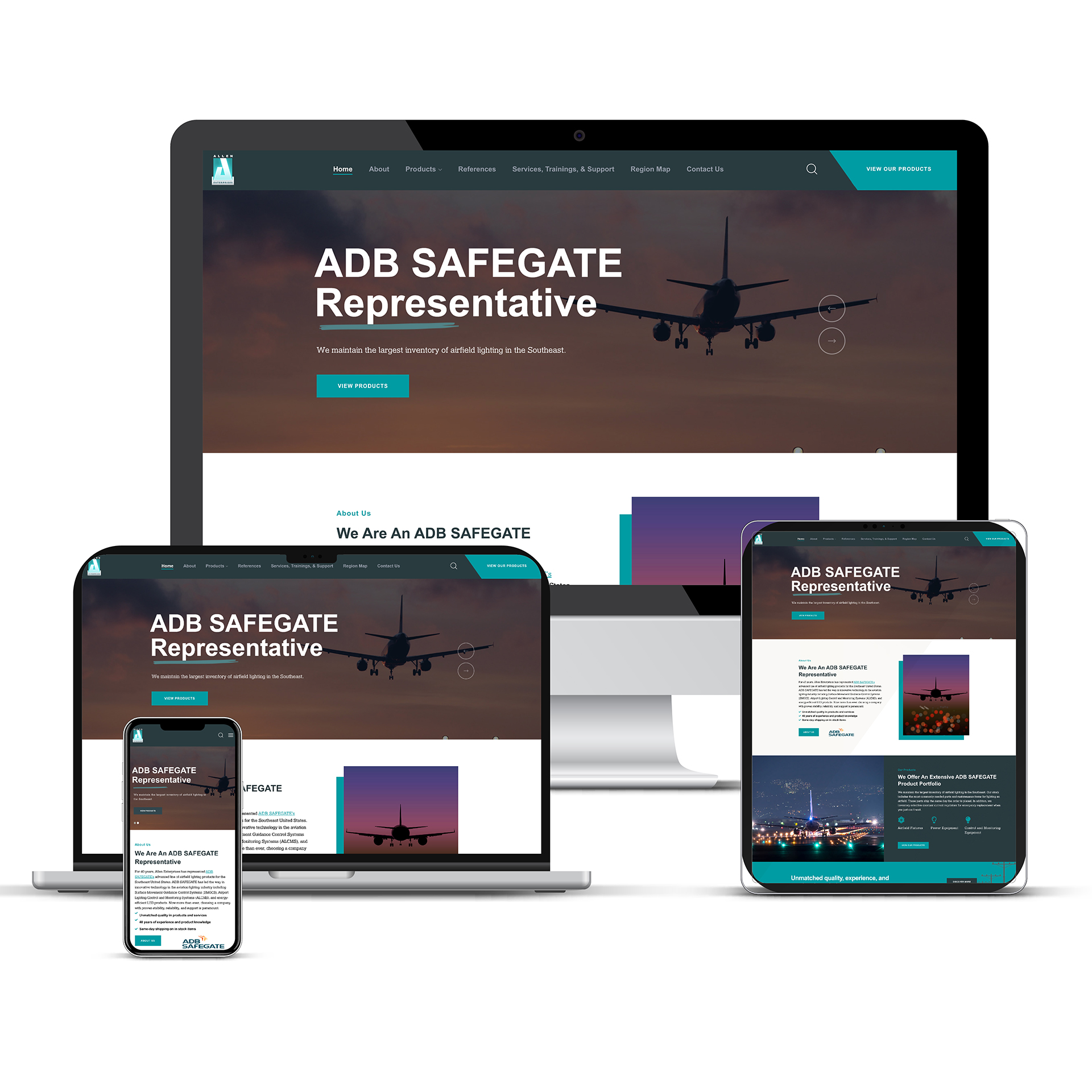

Airport Lights

Website Design Services Portfolio MockUp for Airport Lights

Florida Eye Surgeons And Associates

Website Design Services Portfolio MockUp for Florida Eye Surgeons And Associates

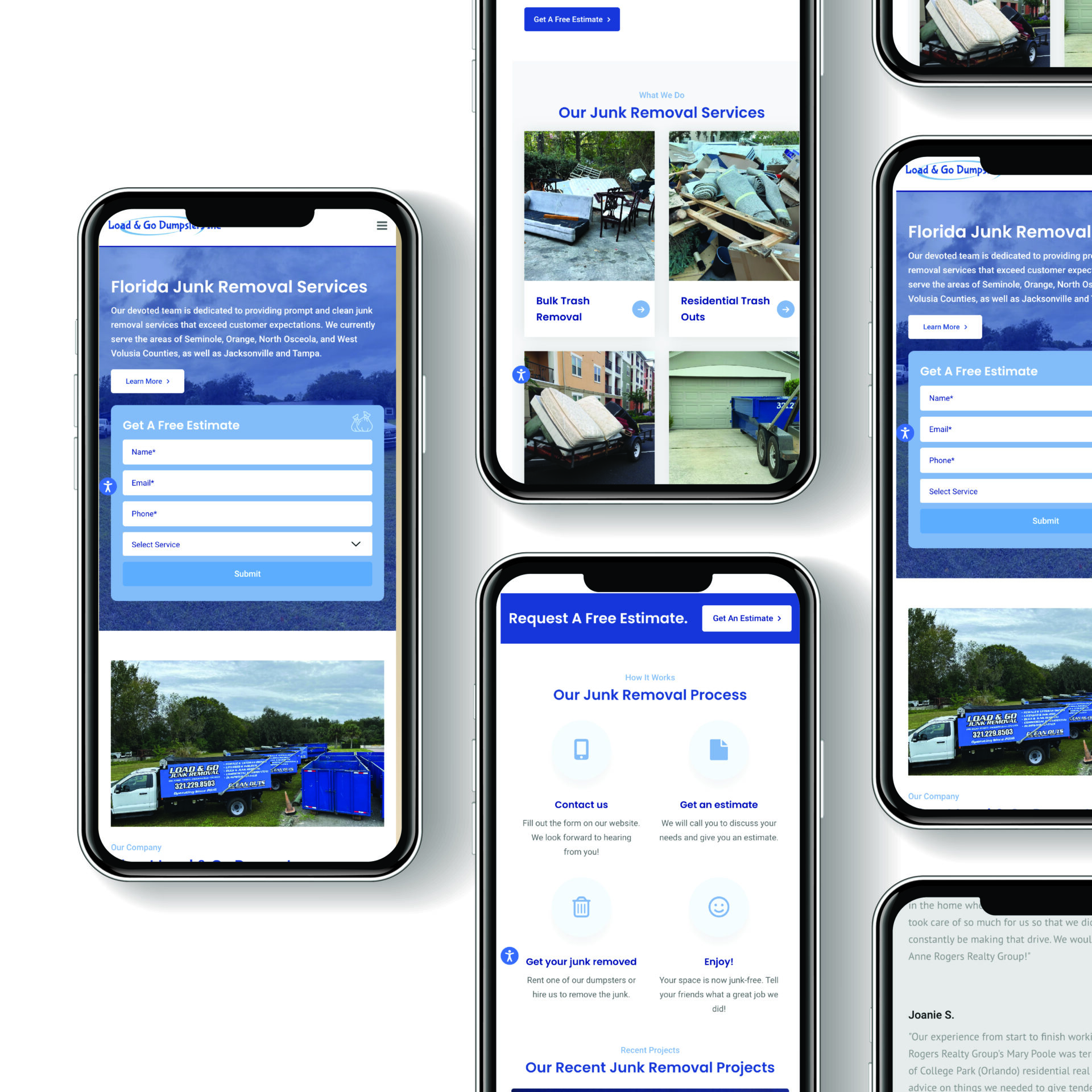

Load & Go Dumpsters

Website Design Services Portfolio MockUp for Load & Go Dumpsters

Meinhart Homes

Website Design Services Portfolio MockUp for Meinhart Homes

Venue Construction Group

Atlantic Care Services

Website Design Services Portfolio MockUp for Atlantic Care Services

M. Lahr Homes

Website Design Services Portfolio MockUp for M. Lahr Homes

Bright Future Electric Panhandle

Website Design Services Portfolio MockUp for Bright Future Electric Panhandle

Schwenn Services

Website Design Services Portfolio MockUp for Schwenn Services

Advantage Roofing

Website Design Services Portfolio MockUp for Advantage Roofing

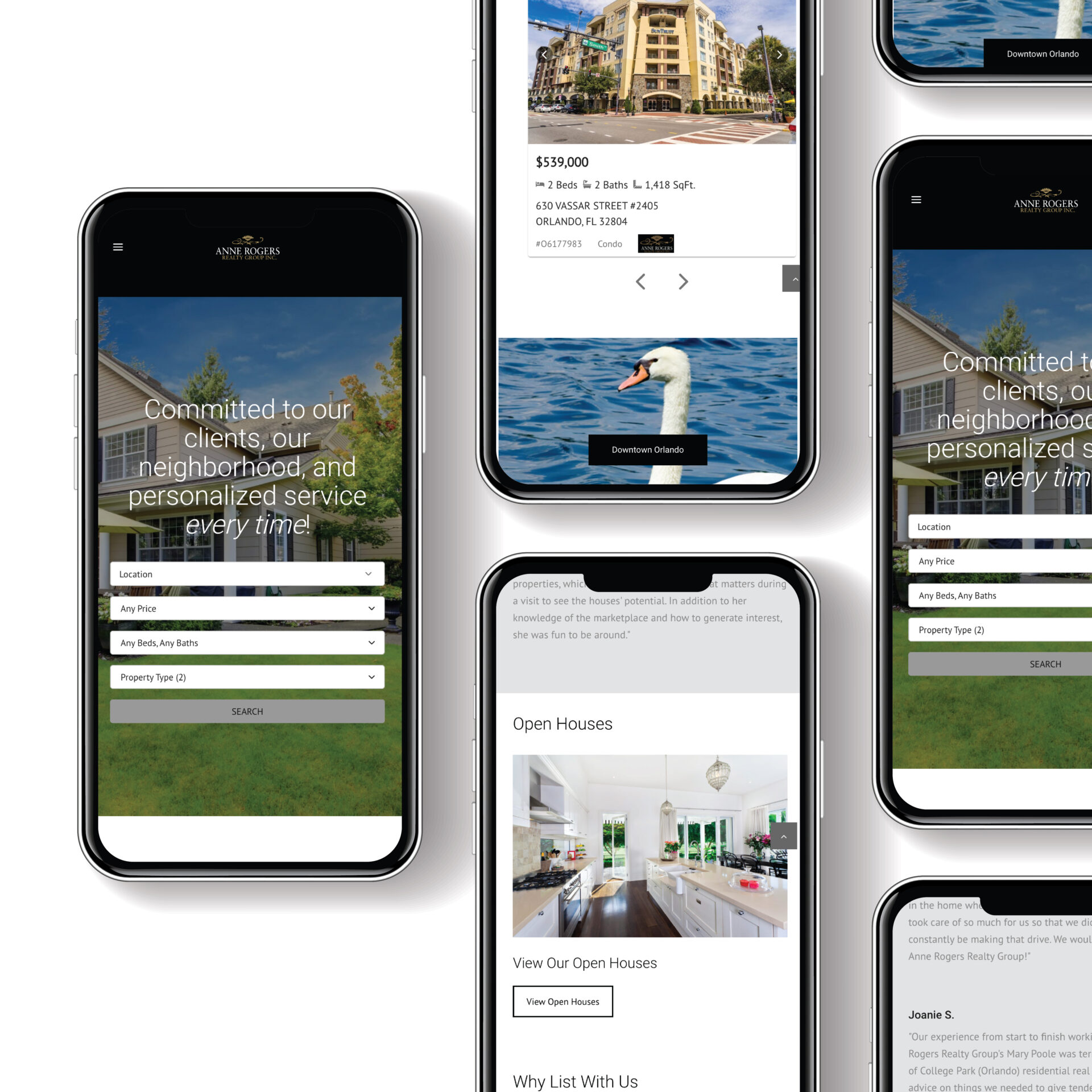

Anne Rogers Realty Group

Website Design Services Portfolio MockUp for Anne Rogers Realty Group

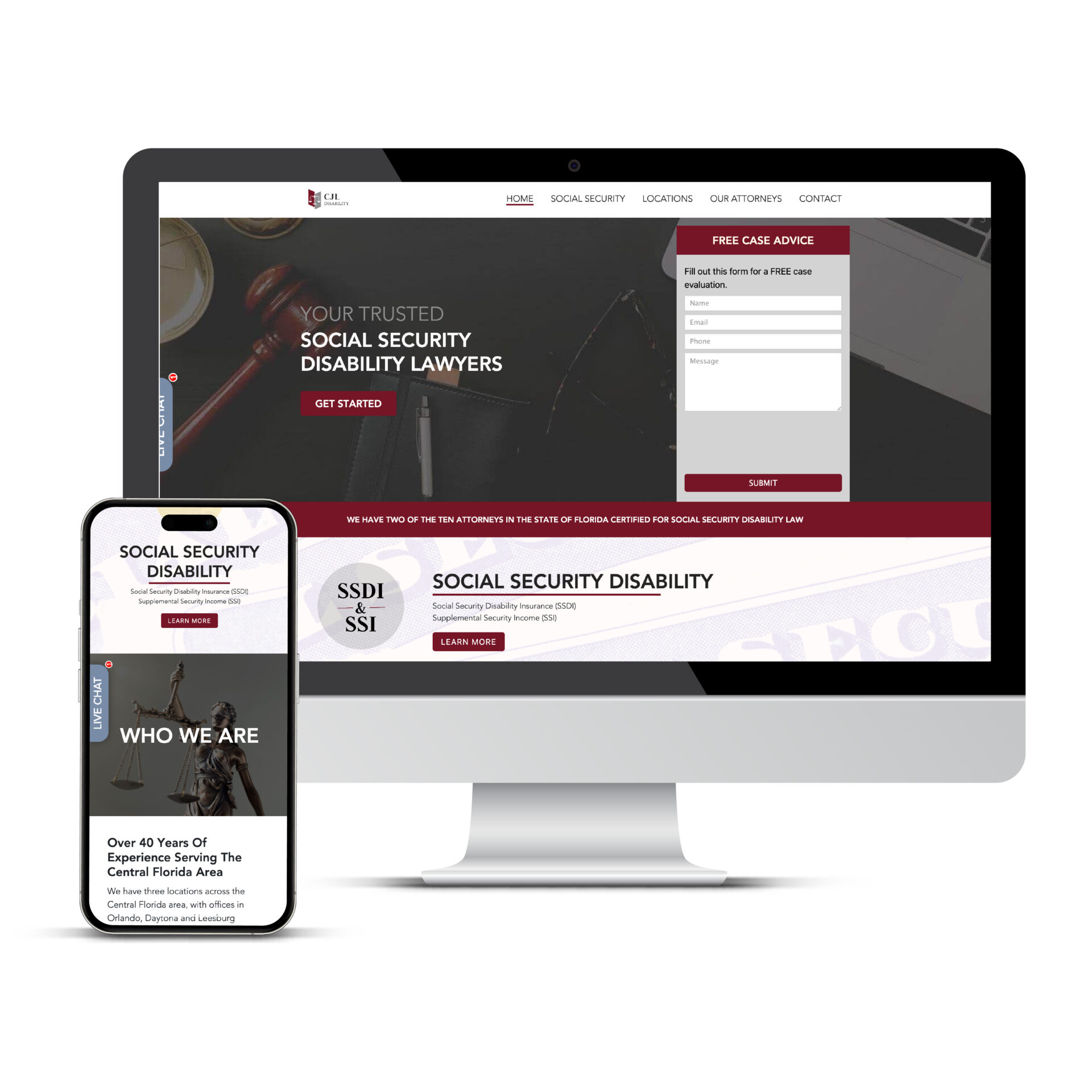

CJL Disability

Website Design Services Portfolio MockUp for CJL Disability

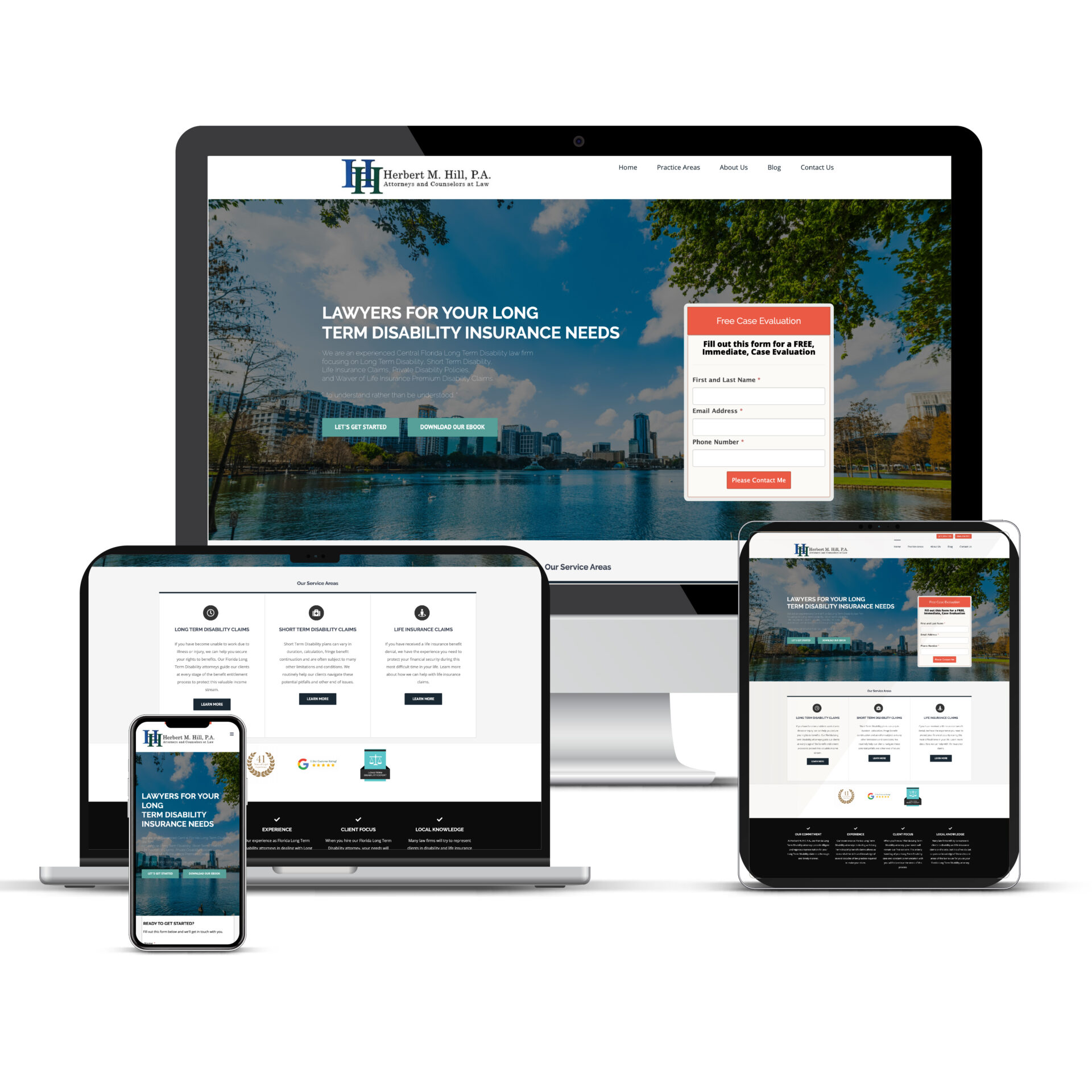

Herbert M. Hill

Website Design Services Portfolio MockUp for Herbert M. Hill

Casais & Prias PLLC

Website Design Services Portfolio MockUp for Casais & Prias PLLC

Acme Environmental Services

Website Design Services Portfolio MockUp for Acme Environmental Services

Kymberly Group

Website Design Services Portfolio MockUp for Kymberly Group

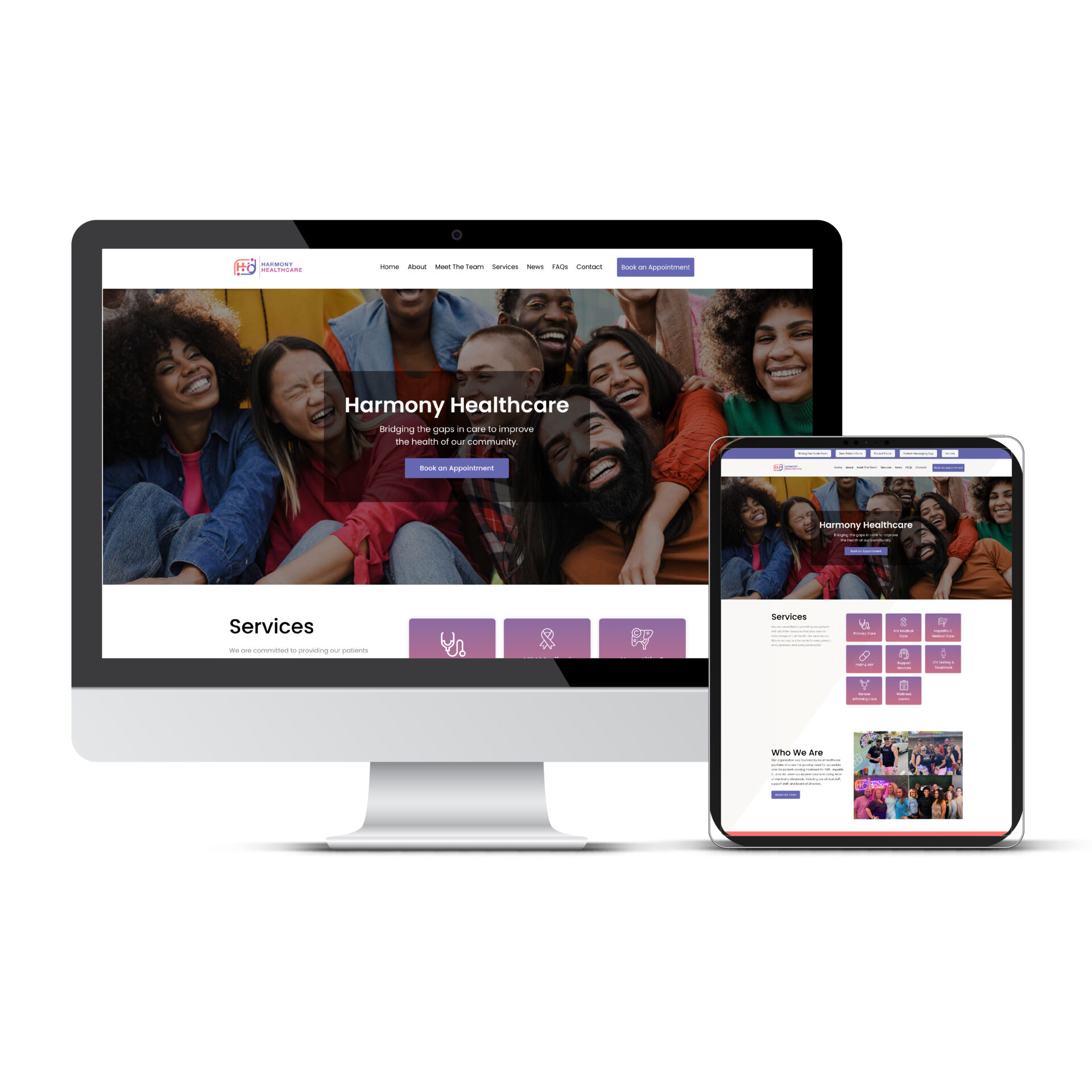

Harmony Healthcare

Website Design Services Portfolio MockUp for Harmony Healthcare

Quality Cable Contractors Inc.

Website Design Services Portfolio MockUp for Quality Cable Contractors Inc.

The College Map

Website Design Services Portfolio MockUp for The College Map

Ortho Biometrix

Website Design Services Portfolio MockUp for Ortho Biometrix

Jager Investigations

Website Design Services Portfolio MockUp for Jager Investigations

Encore Plumbing Inc

Website Design Services Portfolio MockUp for Encore Plumbing Inc

NOLA Dermatology at Mississippi

Website Design Services Portfolio MockUp for NOLA Dermatology at Mississippi

Central Florida Diaper Bank

Website Design Services Portfolio MockUp for Central Florida Diaper Bank

Chameleon Pilates

Website Design Services Portfolio MockUp for Chameleon Pilates

Citrus Dermatology

Website Design Services Portfolio MockUp for Citrus Dermatology

ABC Brokerage

Website Design Services Portfolio MockUp for ABC Brokerage

Breedlove, Dennis & Associates, Inc.

Sauceman Plumbing

Next Level Roofers

Elizabeth Morse Genius Foundation

AGI Construction Services Inc.

CJL Disability

Avennture

CareSeek

Becoming A Local

East Orlando Houses For Sale

Florida Home Team Realty

Boone’s Best

Desire Diesel Repair

Florida Eye Surgeons And Associates

Feel Peace Now

Certified Diesel

Kaleidoscope Interior

Ellison Pools

Eleven Events

Hyser.

Farrah’s Fancies

LEA3 Consulting

All Hands On Language

Match Made In Real Estate

Sandra L. Woodall

PJ Hargreaves

Lindsey Brooke

Florida’s Favorite

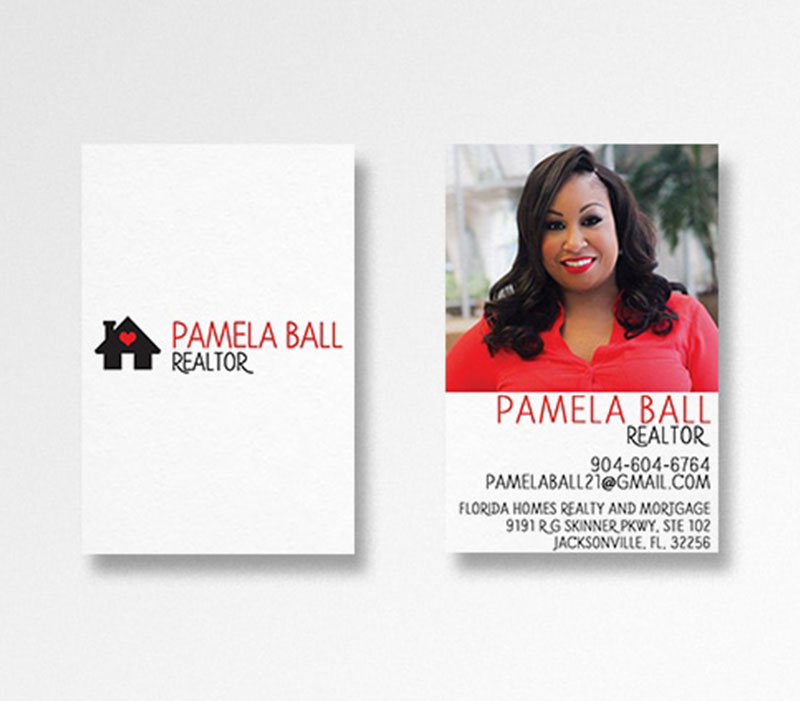

Pamela Ball Realtor

Israoui Law

MammoAid

Kann Advisory Group

Roseus

Sunline

RT Photography

SkyView HD

The Tiny Orchid Co.

The Klein Practice

The Travel Guys

Unsell

Uptown Stitch Design Studio

Winter Park Meditation & Mindfulness

Bambuu Asian Eatery Flyer Design

Roseus Vacations Postcard Design

Hello Pool Side Line Sheet

Becoming a Local Connect Cards

Blake Howard Greeting Card

Blake Howard Business Cards

Print Design

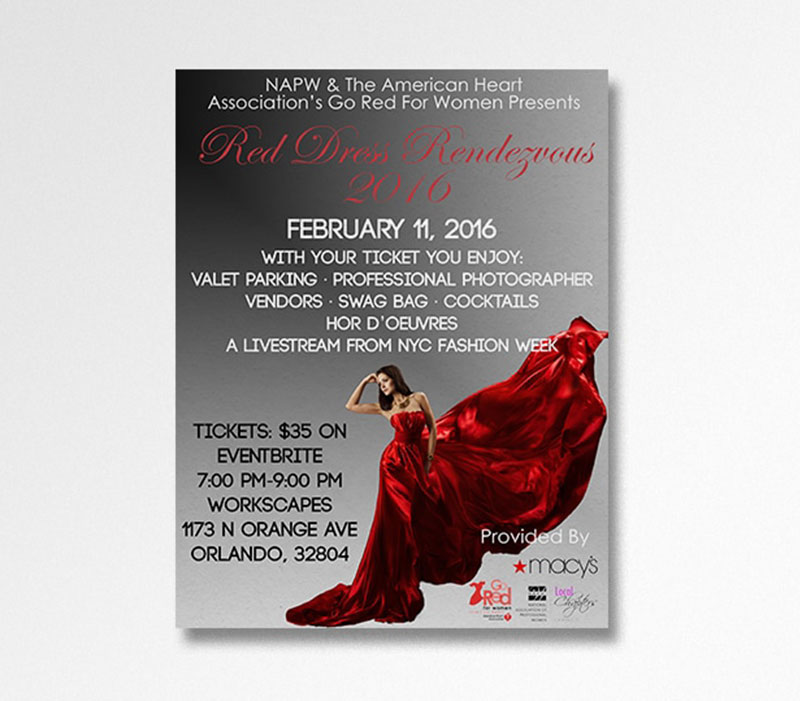

American Heart Association Flyer

Bogo Poster

Engineering Rack Card Front & Back

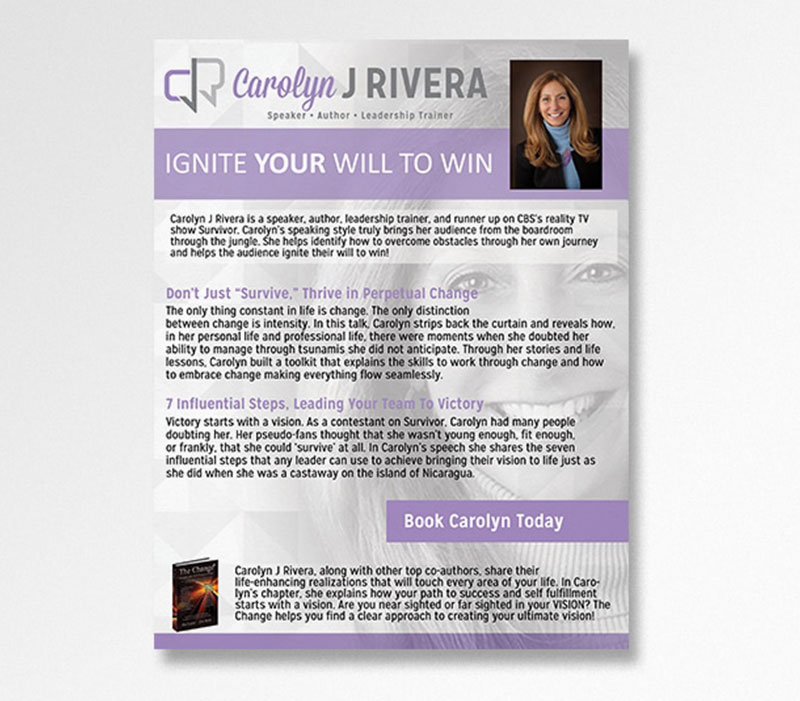

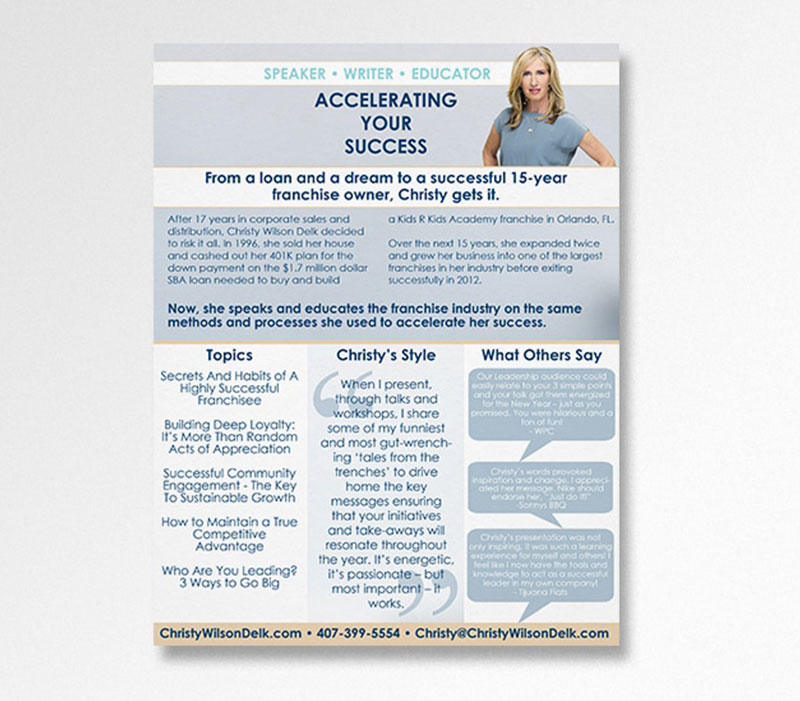

Speaker Sheet

SPEAKER SHEET

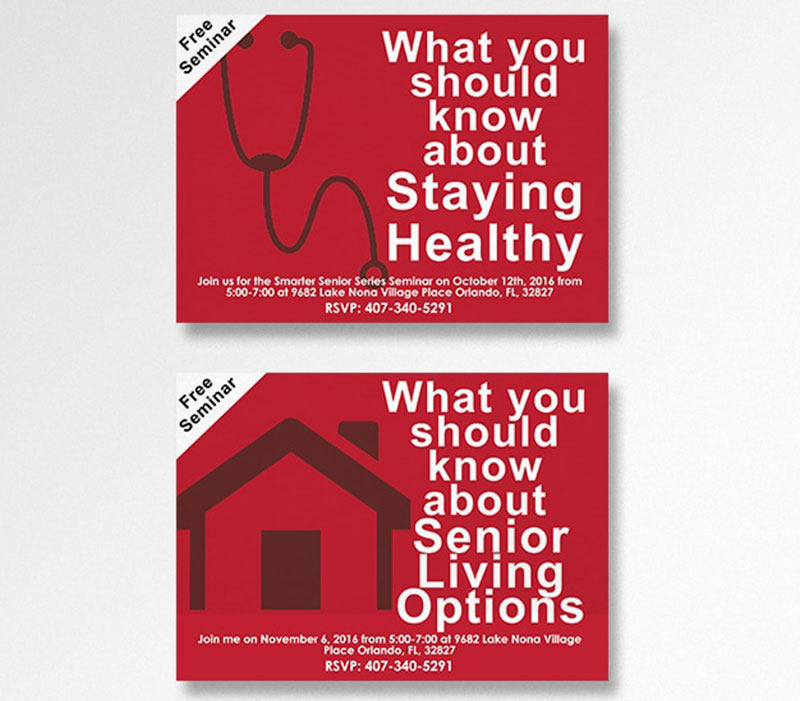

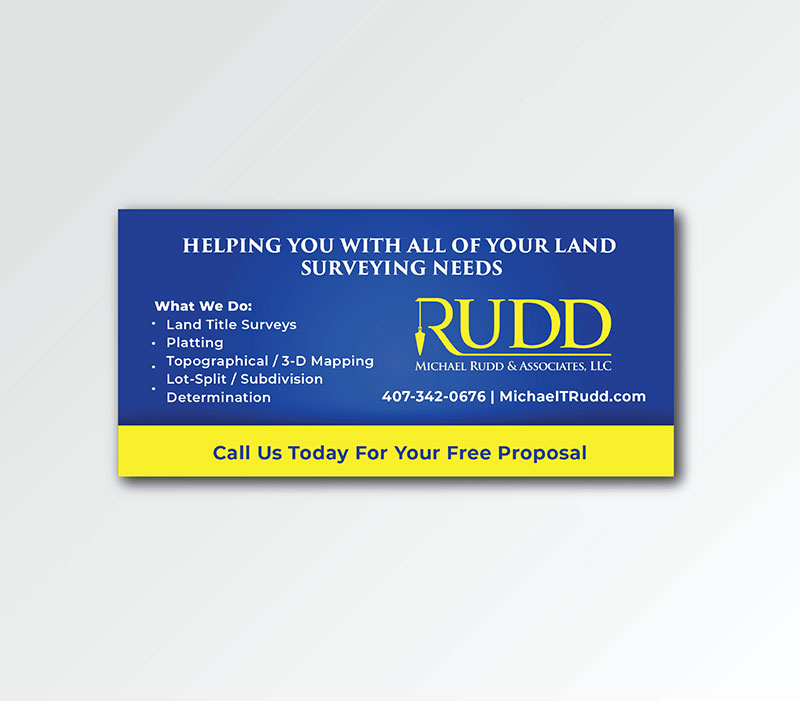

Rack Card Front & Back

Poster

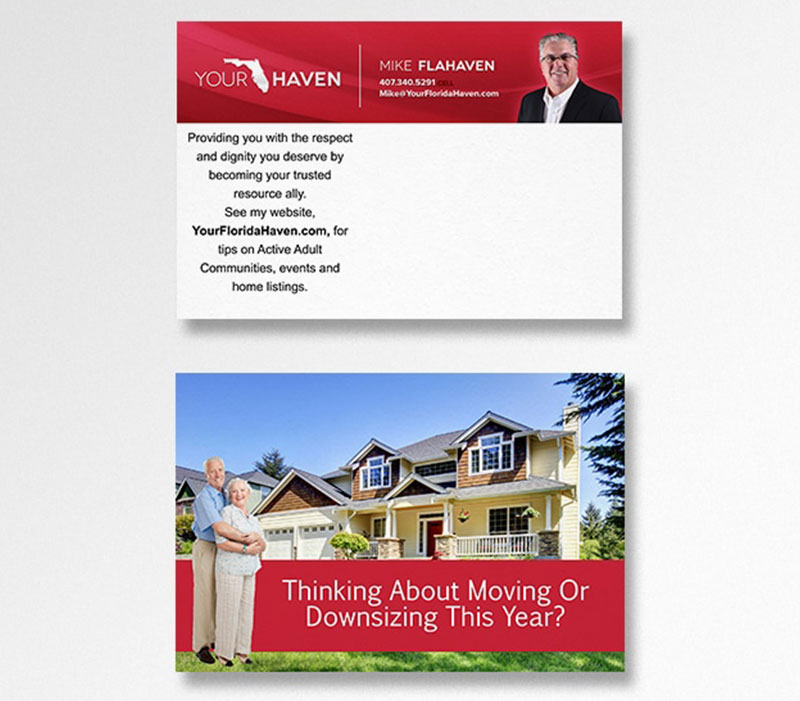

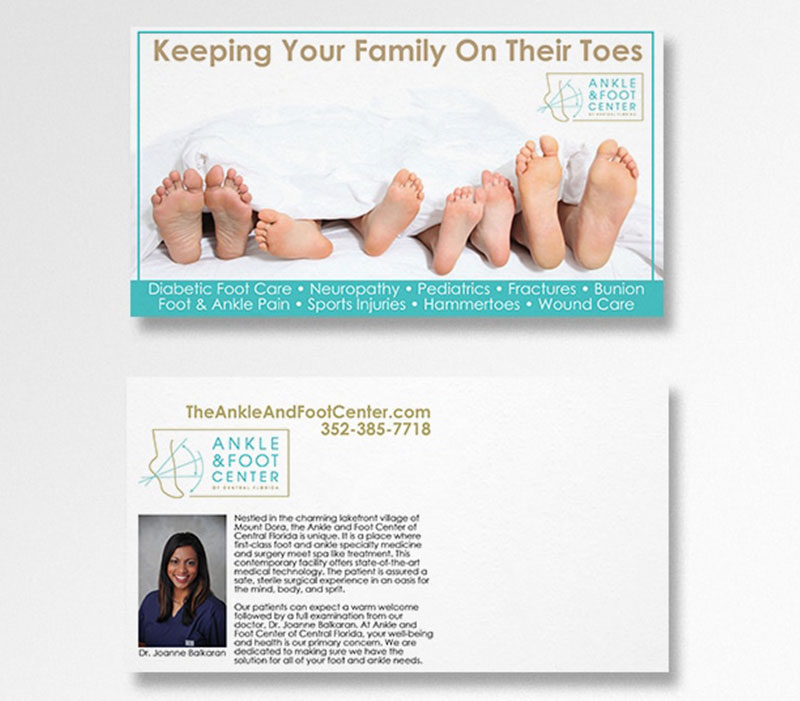

Business Card Front & Back

Business Card Front & Back

Business Card

Business Card

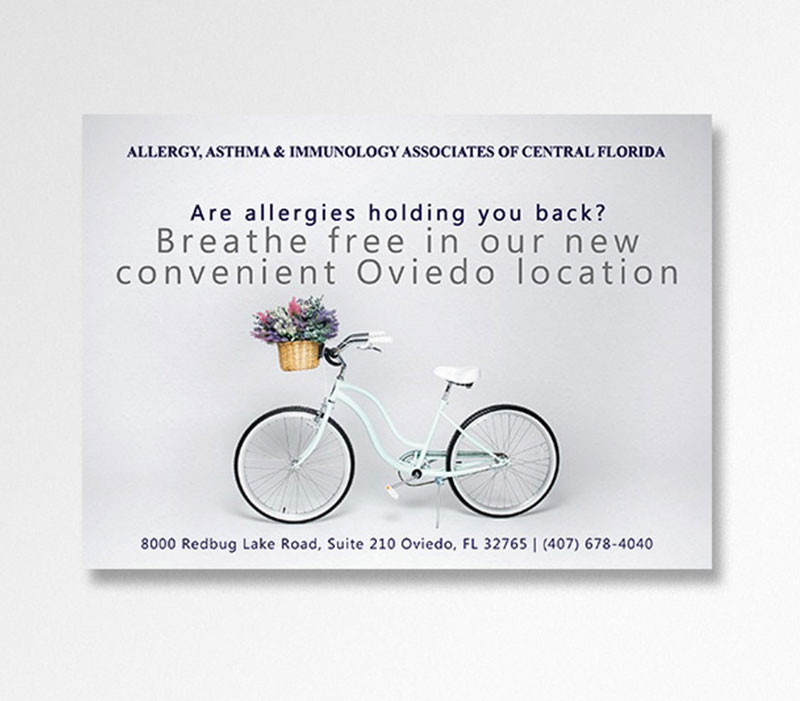

Postcard

Postcard

Postcard

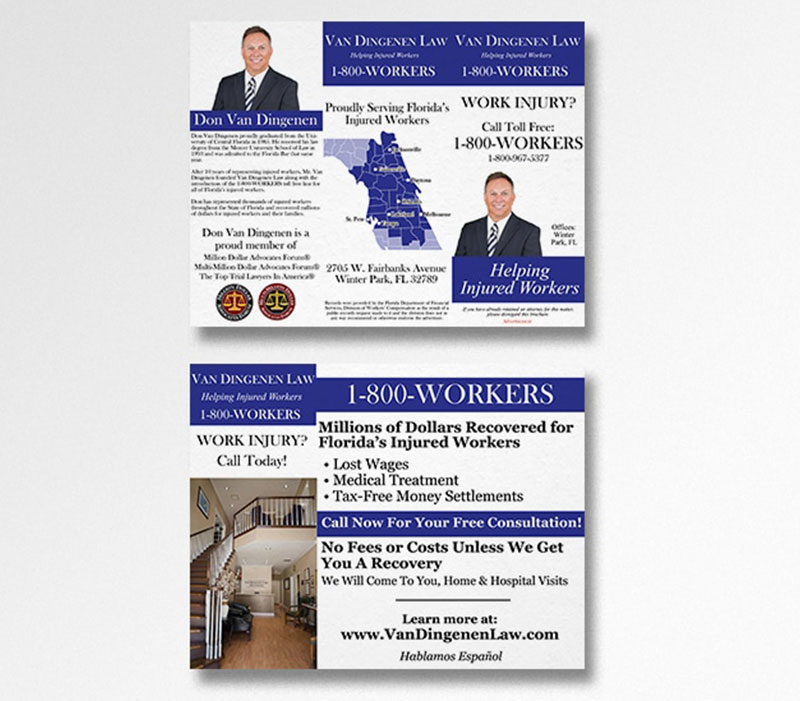

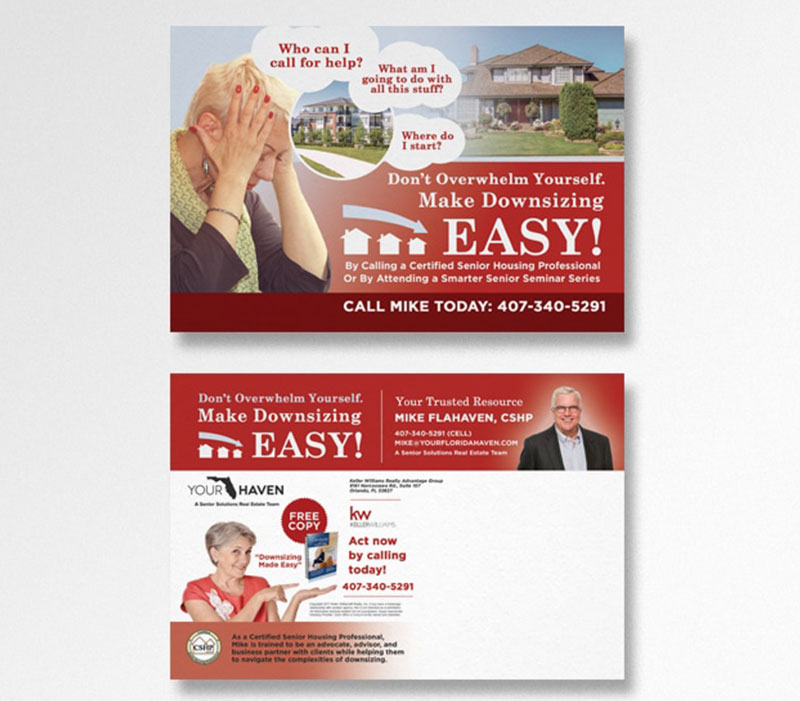

Postcard Front & Back

Postcard Front & Back

Postcard Front

Business Card

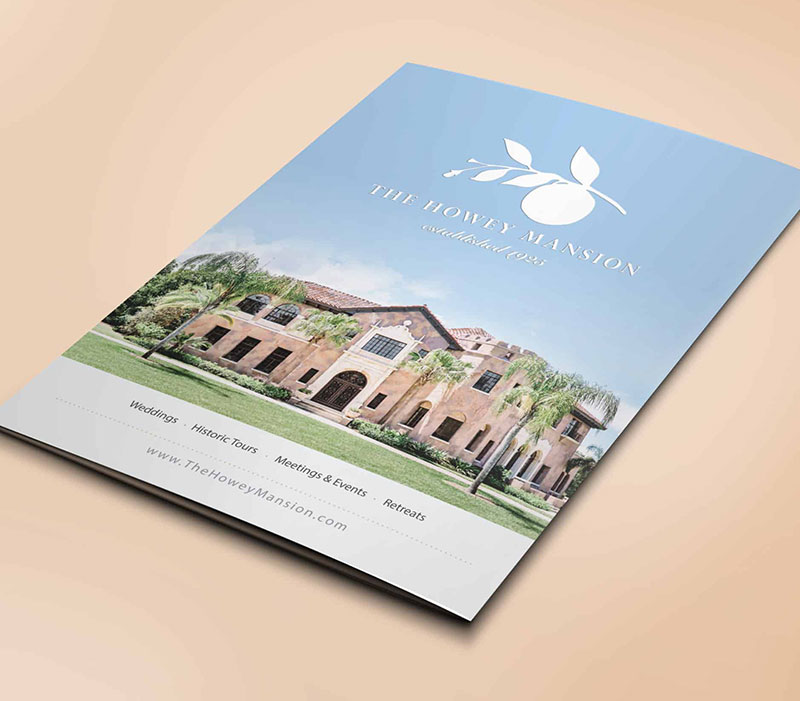

Brochure

Company One Sheet

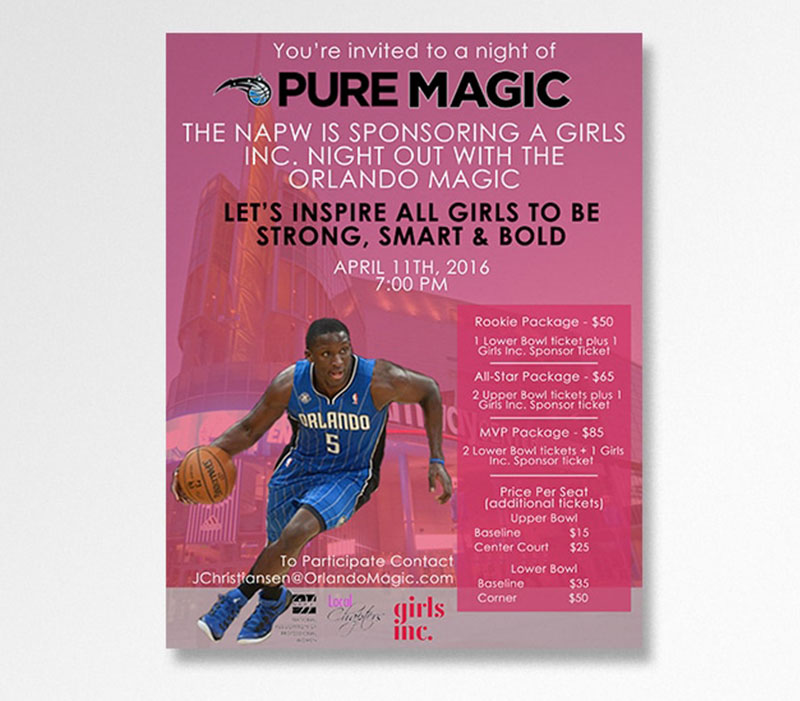

Flyer

Magic & Napw Event

Medical Trifold

Print Flyer

Product Promotion

Print AD

Print AD

Print Flyer

Print Flyer

Postcard

Print Flyer

South Street & CO. Beer Label Mockup

South Street & Co. Coffee Label Mockup

Computer Screen Investigators Print Ad

Folder Design

Howey Mansion Signage

Business Cards

Hand Lotion Packaging Design

Wine Bottle Design & Mockup

Candle Design

Nail Polish Design

Lotion Design

Craft Soda

In Bloom Florist Corporate Brochure

Pillow Design

Brochure

Flyer Design

Business Card Design

Sticker Design

Jewelry Brochure Design

Business Card Design

Face Lotion Design

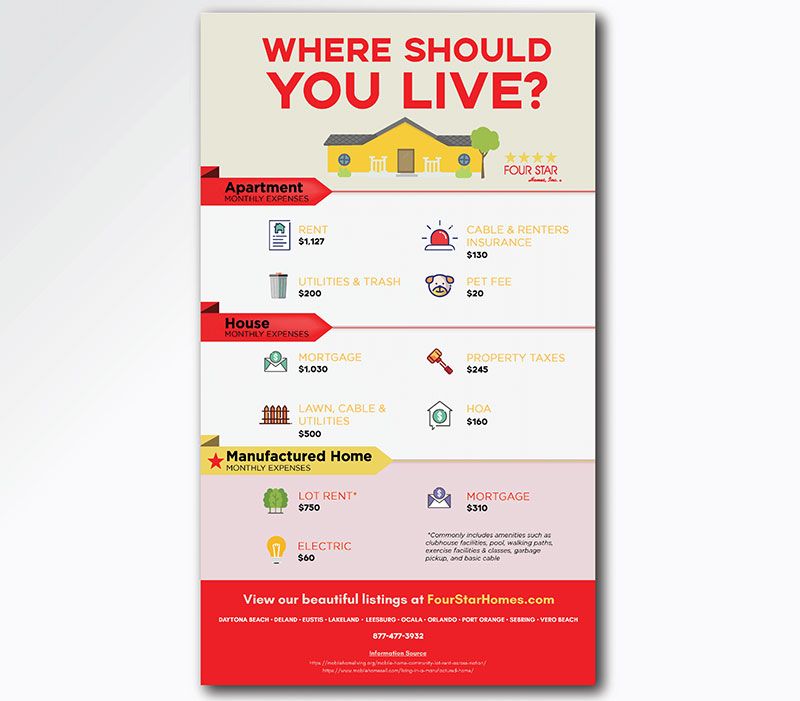

Four Star Homes Real Estate Brochure

Clothing Tag

Four Star Homes Listing Folder

Brochure Mockup Design

Bakery Doughnut Box Packaging

Becoming a Local Orlando Guide

Business Card Mockup

The Julian Whitepaper Mockup

Becoming a Local Window Decal

South Street & Co. Business Card Mockup

Mug Mockup

Michal Rudd AD

Harmony Healthcare Newsletter AD

Four Star Homes Infographic

Ritique Look Book

Website Design

DynaFire

Office Assets, LLC

Website Design Services Portfolio MockUp for Office Assets, LLC

Elizabeth Morse Genius Foundation

Creative Environmental Solutions

Website Design Services Portfolio MockUp for Creative Environmental Solutions

Airport Lights

Website Design Services Portfolio MockUp for Airport Lights

Florida Eye Surgeons And Associates

Website Design Services Portfolio MockUp for Florida Eye Surgeons And Associates

Load & Go Dumpsters

Website Design Services Portfolio MockUp for Load & Go Dumpsters

Meinhart Homes

Website Design Services Portfolio MockUp for Meinhart Homes

Venue Construction Group

Atlantic Care Services

Website Design Services Portfolio MockUp for Atlantic Care Services

M. Lahr Homes

Website Design Services Portfolio MockUp for M. Lahr Homes

Bright Future Electric Panhandle

Website Design Services Portfolio MockUp for Bright Future Electric Panhandle

Schwenn Services

Website Design Services Portfolio MockUp for Schwenn Services

Advantage Roofing

Website Design Services Portfolio MockUp for Advantage Roofing

Anne Rogers Realty Group

Website Design Services Portfolio MockUp for Anne Rogers Realty Group

CJL Disability

Website Design Services Portfolio MockUp for CJL Disability

Herbert M. Hill

Website Design Services Portfolio MockUp for Herbert M. Hill

Casais & Prias PLLC

Website Design Services Portfolio MockUp for Casais & Prias PLLC

Acme Environmental Services

Website Design Services Portfolio MockUp for Acme Environmental Services

Kymberly Group

Website Design Services Portfolio MockUp for Kymberly Group

Harmony Healthcare

Website Design Services Portfolio MockUp for Harmony Healthcare

Quality Cable Contractors Inc.

Website Design Services Portfolio MockUp for Quality Cable Contractors Inc.

The College Map

Website Design Services Portfolio MockUp for The College Map

Ortho Biometrix

Website Design Services Portfolio MockUp for Ortho Biometrix

Jager Investigations

Website Design Services Portfolio MockUp for Jager Investigations

Encore Plumbing Inc

Website Design Services Portfolio MockUp for Encore Plumbing Inc

NOLA Dermatology at Mississippi

Website Design Services Portfolio MockUp for NOLA Dermatology at Mississippi

Central Florida Diaper Bank

Website Design Services Portfolio MockUp for Central Florida Diaper Bank

Chameleon Pilates

Website Design Services Portfolio MockUp for Chameleon Pilates

Citrus Dermatology

Website Design Services Portfolio MockUp for Citrus Dermatology

ABC Brokerage

Website Design Services Portfolio MockUp for ABC Brokerage

Breedlove, Dennis & Associates, Inc.

Logo Design

Sauceman Plumbing

Next Level Roofers

Elizabeth Morse Genius Foundation

AGI Construction Services Inc.

CJL Disability

Avennture

CareSeek

Becoming A Local

East Orlando Houses For Sale

Florida Home Team Realty

Boone’s Best

Desire Diesel Repair

Florida Eye Surgeons And Associates

Feel Peace Now

Certified Diesel

Kaleidoscope Interior

Ellison Pools

Eleven Events

Hyser.

Farrah’s Fancies

LEA3 Consulting

All Hands On Language

Match Made In Real Estate

Sandra L. Woodall

PJ Hargreaves

Lindsey Brooke

Florida’s Favorite

Pamela Ball Realtor

Israoui Law

MammoAid

Kann Advisory Group

Roseus

Sunline

RT Photography

SkyView HD

The Tiny Orchid Co.

The Klein Practice

The Travel Guys

Unsell

Uptown Stitch Design Studio

Winter Park Meditation & Mindfulness

Design Work